LMT070DNCFWD-NNA

LCD Module User Manual

Prepared by:

Checked by:

Approved by:

Huchubin

Date: 2020-12-12

Date:

Date:

Rev.

Descriptions

Edit

Release Date

0.1

Preliminary release

Huchubin

2020-12-12

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 1 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

Table of Content

1.

Applications................................................................................................ ........................... 3

2. General Specification ................................................................................................ ............ 3

3. Block Diagram................................................................................................ ........................ 3

4. Terminal Function (Input Terminal)................................................................ ...................... 4

4.1

TFT Input Terminal................................................................................................................................ ................. 4

4.2

Touch Panel Terminal Functions............................................................................................................................ 5

5.

Absolute Maximum Ratings................................................................................................ .. 5

6. Electrical Characteristics ................................................................................................ ...... 5

6.1

DC Characteristics ................................................................................................................................ ................. 5

6.2

Current Consumption................................................................................................................................ ............. 5

6.3

LED Backlight Circuit Characteristics................................................................................................ ..................... 6

6.4

Touch panel Characteristics................................................................................................................................ ... 6

6.5

Power Sequence................................................................................................................................ .................... 7

7.

AC Characteristics................................................................................................ ................. 7

7.1

Timing Characteristics................................................................................................................................ ............ 7

7.2

Input Clock and Data Timing Diagram ................................................................................................ ................... 8

7.3

Timing ................................................................................................................................................................ .... 8

7.4

Data Input Format ................................................................................................................................ .................. 9

7.5

Optical Characteristics ......................................................................................................................................... 10

8. LCD Module Design and Handling Precautions ................................................................. 11

9. CTP Mounting Instructions ................................................................................................. 12

10. RTP Mounting Instructions ................................................................................................. 13

Warranty ...................................................................................................................................... 15

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 2 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

1. Applications

This Module is designed for portable DVD, GPS car TV & PMP(portable multimedia player)

application which require high quality flat panel displays. It is also a good substitute for many

outmoded CSTN module in the industrial application.

This product is composed of a TFT-LCD panel, driver ICs, FPC and LED backlight unit.

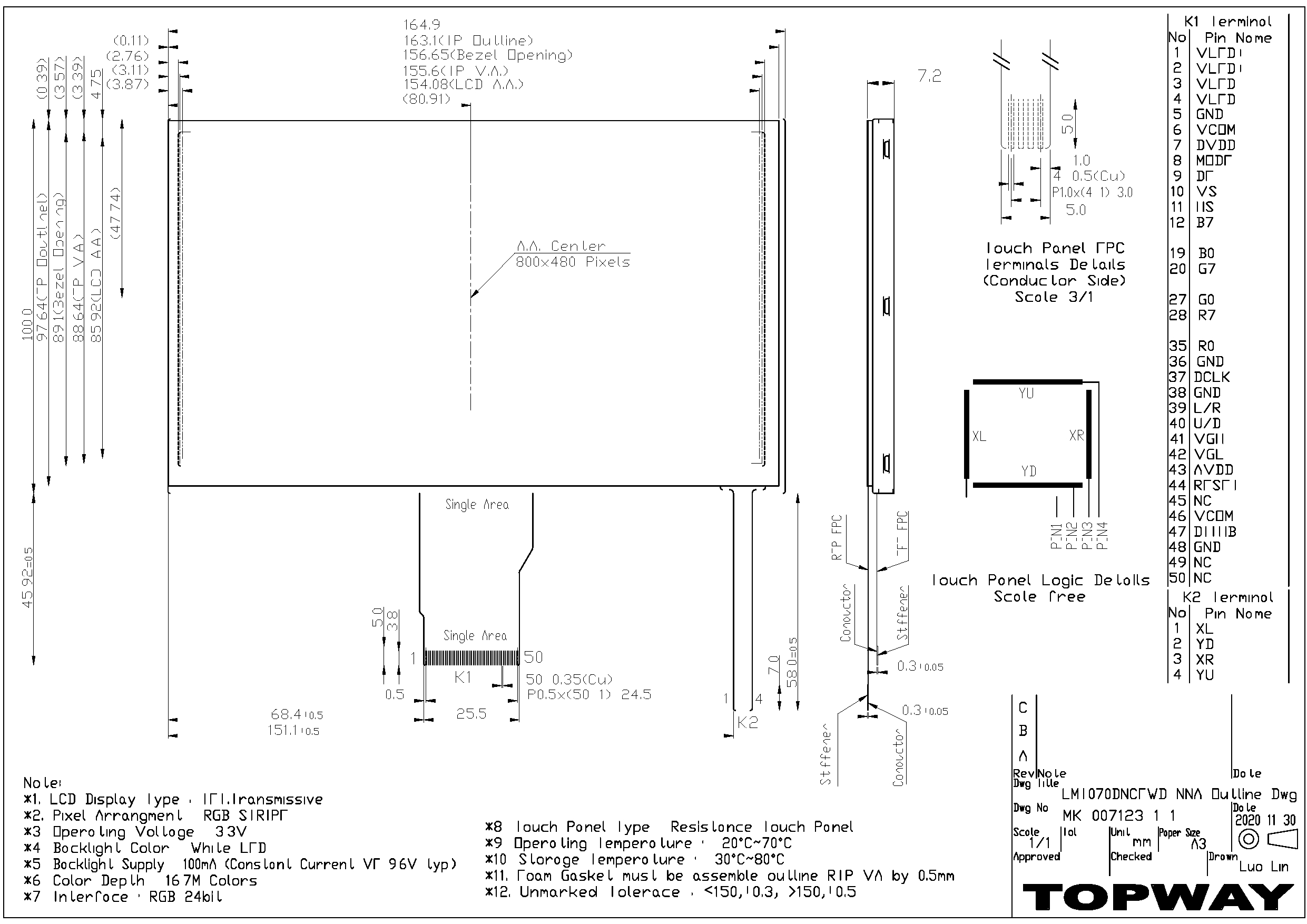

2. General Specification

Signal Interface :

Digital 24-bits RGB

Display Technology :

a-Si TFT active matrix

Display Mode :

TN Type Full Color / Transmissive / Normal White

Screen Size(Diagonal) :

7.0”

Outline Dimension :

164.9x 100.0 x 7.2 (mm)

(see attached drawing for details)

Active Area :

154.08 x 85.92 (mm)

Number of dots :

800 x 480

Pixel Pitch :

0.1926 x 0.1790 (mm)

Pixel Configuration :

RGB Stripe

Backlight :

LED

Surface Treatment :

Anti-Glare Treatment

Viewing Direction :

6 o’clock(Gray scale Inversion) (*1)

12 o’clock (*2)

Operating Temperature :

-20 ~ +70°C

Storage Temperature :

-30 ~ +80°C

Touch Panel Type:

Four-wire Resistive

Note:

*1. For saturated color display content (eg. pure-red, pure-green, pure-blue or pure-colors-combinations).

*2. For “color scales” display content.

*3. Color tone may slightly change by temperature and driving condition.

3. Block Diagram

XL, YD, XR, YU

Touch Panel

VLED+,VLED-

Backlight Circuit

DVDD, GND, AVDD

VCOM

VGH, VGL

7’’ TFT Panel

DCLK

DE, HS, V

S

MODE

DITHB

R0~R7, G0~G7, B0~B7

Source Driver

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 3 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

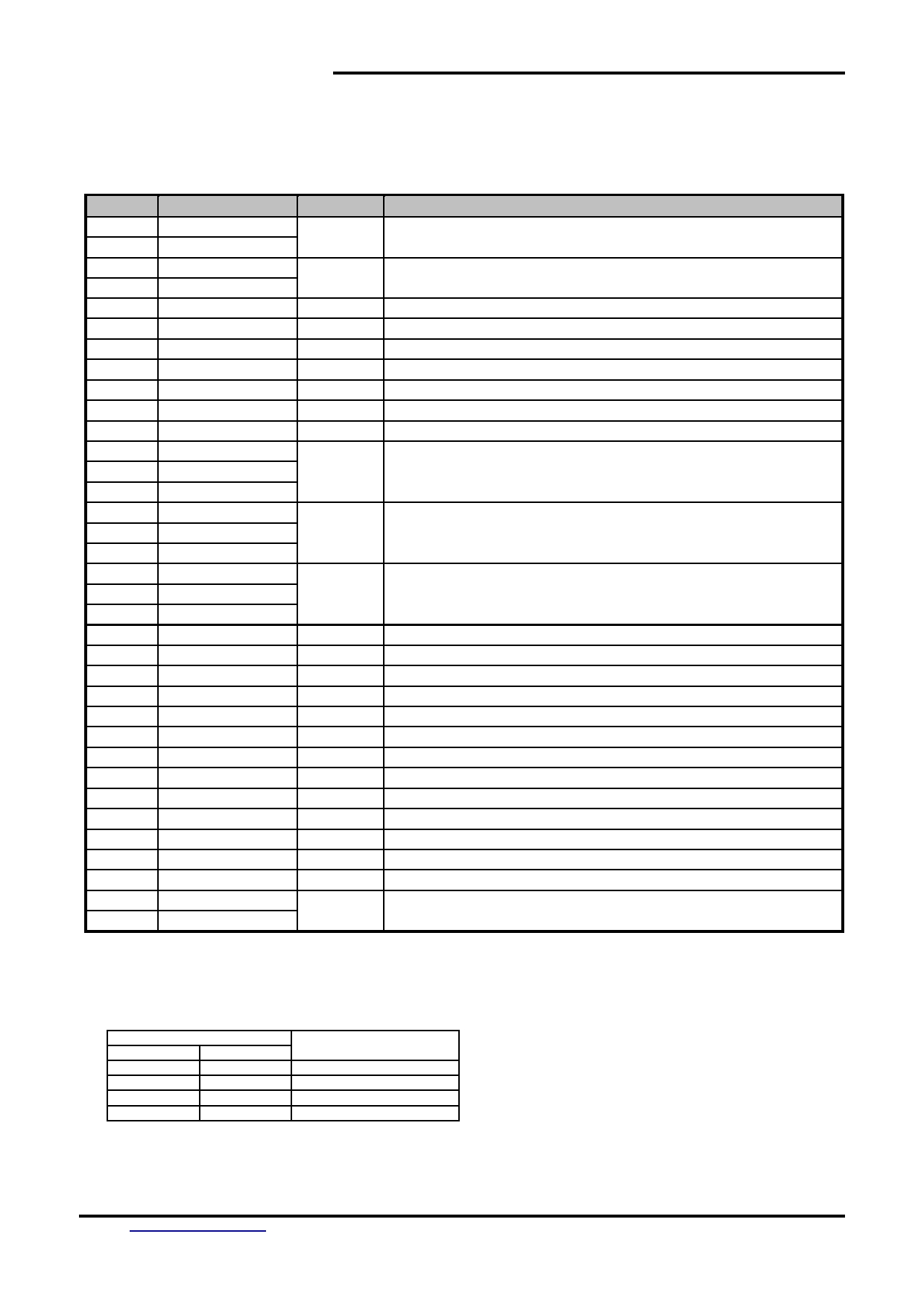

4. Terminal Function (Input Terminal)

4.1

TFT Input Terminal

Pin No.

Pin Name

I/O

Descriptions

1

VLED+

2

VLED+

Power

Positive Backlight Power Supply

3

VLED-

4

VLED-

Power

Negative Backlight Power Supply

5

GND

Power

Power GND (0V)

6

VCOM

Input

Common voltage

7

DVDD

Power

Power for Digital Circuit

8

MODE

Input

DE/SYNC mode select (*1)

9

DE

Input

Data input enable

10

VS

Input

Vertical Sync Input

11

HS

Input

Horizontal Sync Input

12

B7

:

:

Input

8bit Data for Blue

19

B0

20

G7

:

:

Input

8bit Data for Green

27

G0

28

R7

:

:

Input

8bit Data for Red

35

R0

36

GND

Power

Power GND (0V)

37

DCLK

Input

Sample clock(*2)

38

GND

Power

Power GND (0V)

39

L/R

Input

Left / right selection (*3)

40

U/D

Input

Up/down selection (*3)

41

VGH

Power

Gate ON Voltage

42

VGL

Power

Gate OFF Voltage

43

AVDD

Power

Power for Analog Circuit

44

RESET

Input

Global reset pin (*4)

45

NC

-

No connection

46

VCOM

Input

Common Voltage

47

DITHB

Input

Dithering function (*5)

48

GND

Power

Power GND (0V)

49

NC

-

50

NC

No connection

Note:

* 1: DE/SYNC mode select. Normally pull high.

When select DE mode, MODE=”1”, VS and HS must pull high.

When select SYNC mode, MODE= “0”, DE must be grounded.

* 2: Data shall be latched at the falling edge of DCLK.

* 3: Selection of scanning mode

Setting of scan control input

Scanning direction

U/D

L/R

GND

DVDD

Up to down, left to right

DVDD

GND

Down to up, right to left

GND

GND

Up to down, right to left

DVDD

DVDD

Down to up, left to right

*4: Global reset pin. Active low to enter reset state. Suggest to connect with an RC reset circuit for stability. Normally pull high.

*5: Dithering function enable control, normally pull high.

When DITHB=¡±1¡±,Disable internal dithering function,

When DITHB=¡±0¡±,Enable internal dithering function,

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 4 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

4.2

Touch Panel Terminal Functions

Pin No. Pin Name

I/O

Descriptions

1

XL

Passive

Left Side sense Terminal

2

YD

Passive

Down Side sense Terminal

3

XR

Passive

Right Side sense Terminal

4

YU

Passive

Up Side sense Terminal

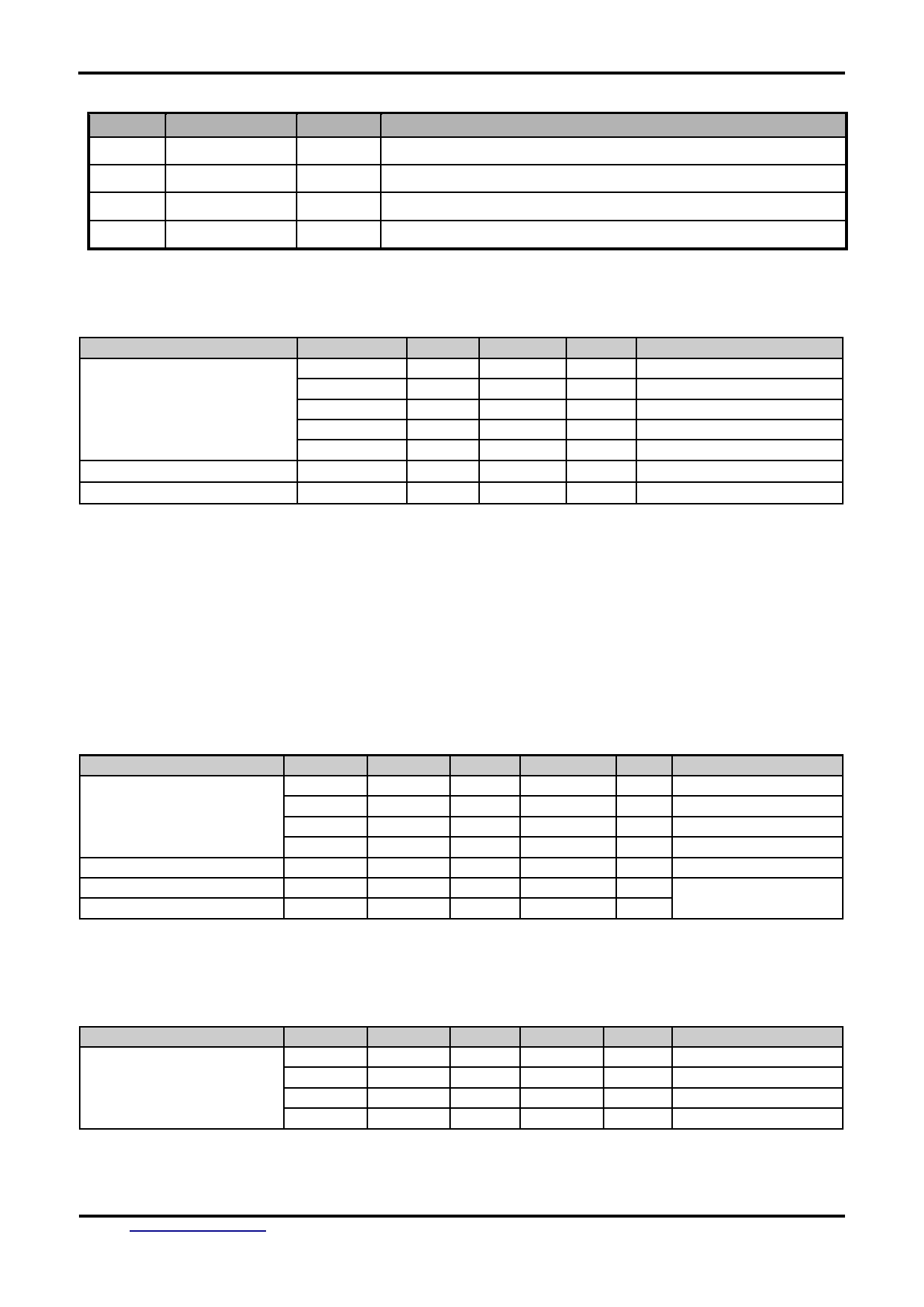

5. Absolute Maximum Ratings

Items

Symbol

Min.

Max.

Unit

Condition

DVDD

-0.3

3.96

V

AVDD

6.5

13.5

V

Power voltage

VGH

-0.3

40.0

V

VGL

-20.0

0.3

V

VGH -VGL

-

40.0

V

Operating Temperature

TOP

-20

70

° C

No Condensation

Storage Temperature

TST

-30

80

° C

No Condensation

Note:

*1. This rating applies to all parts of the module. And should not be exceeded.

*2. The operating temperature only guarantees operation of the circuit. The contrast, response speed,

and the other specification related to electro-optical display quality is determined at the room temperature, T OP =25.

*3. Ambient temperature when the backlight is lit (reference value)

*4. Any Stresses exceeding the Absolute Maximum Ratings may cause substantial damage to the device. Functional

operation of this device at other conditions beyond those listed in the specification is not implied and prolonged

exposure to extreme conditions may affect device reliability.

6. Electrical Characteristics

6.1

DC Characteristics

Items

Symbol

Min.

Typ.

Max.

Unit Remark

DVDD

3.0

3.3

3.6

V

*2

Power voltage

AVDD

10.2

10.4

10.6

V

VGH

15

16

17

V

VGL

-7.5

-7.0

-6.5

V

Input signal voltage

VCOM

4.05

4.15

4.25

V

Input logic high voltage

VIH

0.7VDD

-

DVDD

V

Input logic low voltage

VIL

0

-

0.3DVDD

V

*3

Note:

*1.Be sure to apply DVDD and VGL to the LCD first, and then apply VGH.

*2: DVDD setting should match the signals output voltage (refer to Note 3) of customer’s system board.

*3: DCLK,HS,VS,RESET,U/D, L/R,DE,R0~R7,G0~G7,B0~B7,MODE,DITHB.

6.2

Current Consumption

Items

Symbol

Min.

Typ.

Max.

Unit

Remark

I GH

0.05

0.2

1.0

mA

VGH = 15.0V

Current for Driver

I GL

0.2

0.5

1.0

mA

VGL = -10.0V

I DVDD

1

4.0

10

mA

DVDD=3.3V

I AVDD

5

20

30

mA

AVDD=10.4V

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 5 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

6.3

LED Backlight Circuit Characteristics

Top=25¡æ

Items

Symbol

MIN.

TYP.

MAX.

Unit

Note

Forward Voltage

Vf BLA

9.0

9.6

10.5

V

If=100mA

Forward Current

If BLA

-

100.0

-

mA

Cautions:

Exceeding the recommended driving current could cause substantial damage to the backlight and shorten its lifetime.

6.4

Touch Panel Characteristics

Items

MIN.

TYP.

MAX.

Unit

Note

Operating Voltage

-

5.0

-

V

-

Operating Force

100

-

160

g

-

Life Time

-

1,000,000

-

times

-

X Resistance

100

-

400

Ω

-

Y Resistance

450

-

950

Ω

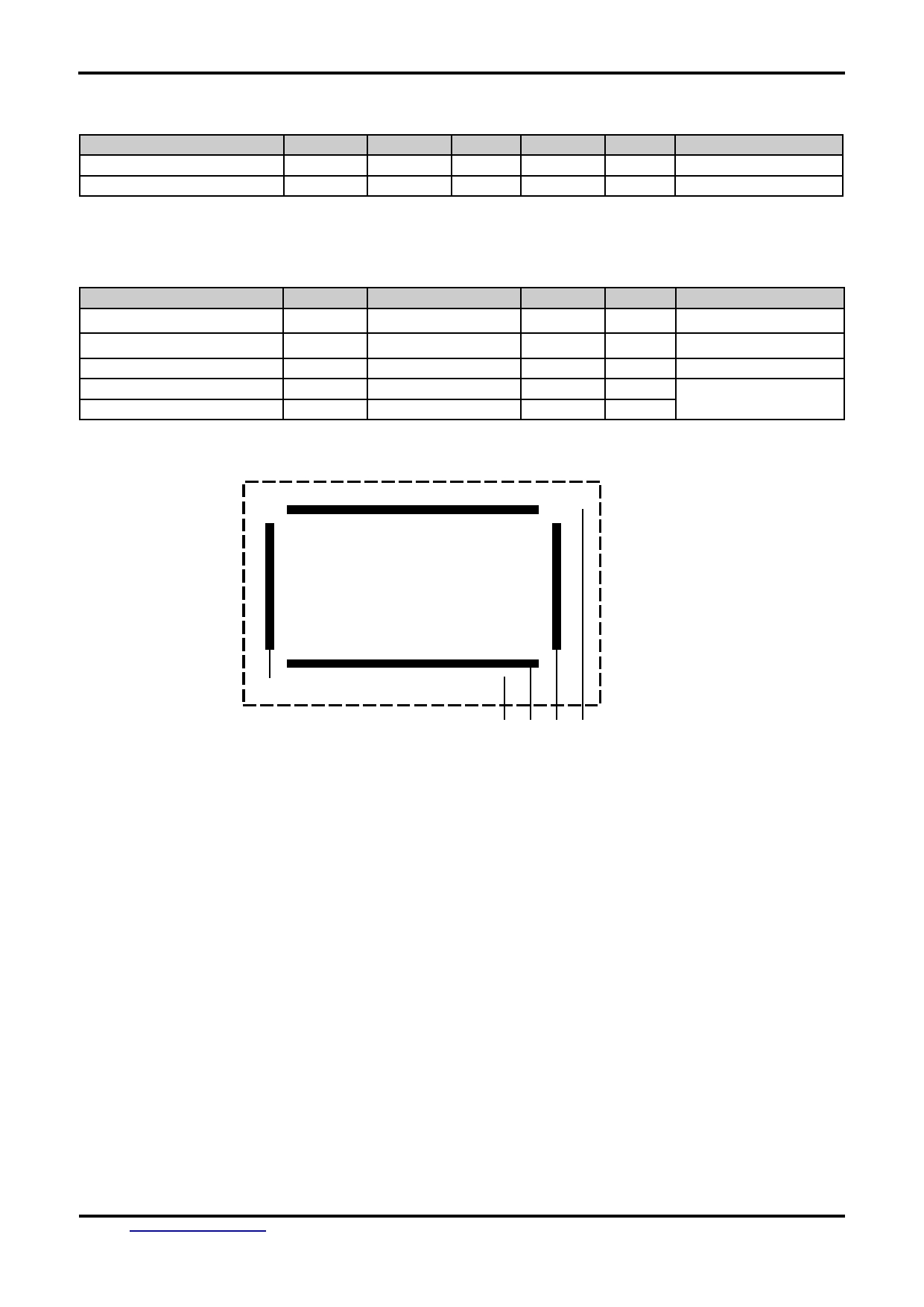

Touch Panel Logic Details

YU

XL

XR

YD

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 6 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

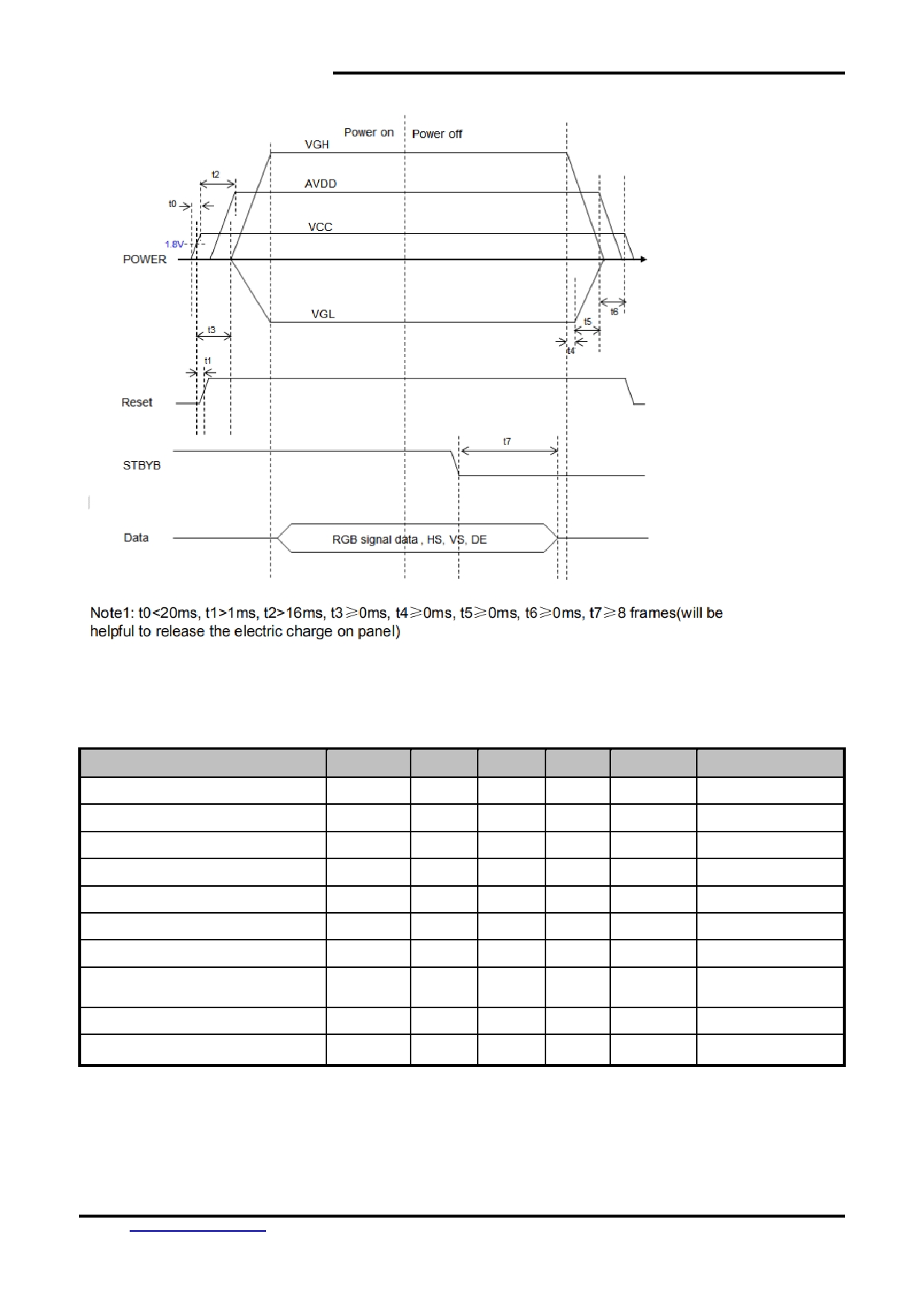

6.5

Power Sequence

7. AC Characteristics

7.1

Timing Characteristics

Item

Symbol

MIN.

TYP.

MAX.

Unit

Remark

HS setup time

Thst

8

-

-

ns

HS hold time

Thhd

8

-

-

ns

VS setup time

Tvst

8

-

-

ns

VS hold time

Tvhd

8

-

-

ns

Data setup time

Tdsu

8

-

-

ns

Data hole time

Tdhd

8

-

-

ns

DE setup time

Tesu

8

-

-

ns

DV DD Power On Slew rate

TPOR

-

-

20

ms

From 0 to 90%

DV DD

DCLK cycle time

Tcph

20

-

-

ns

DCLK pulse duty

Tcwh

40

50

60

%

Note: For the details of the timing, please see the Driver IC data sheet.

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 7 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

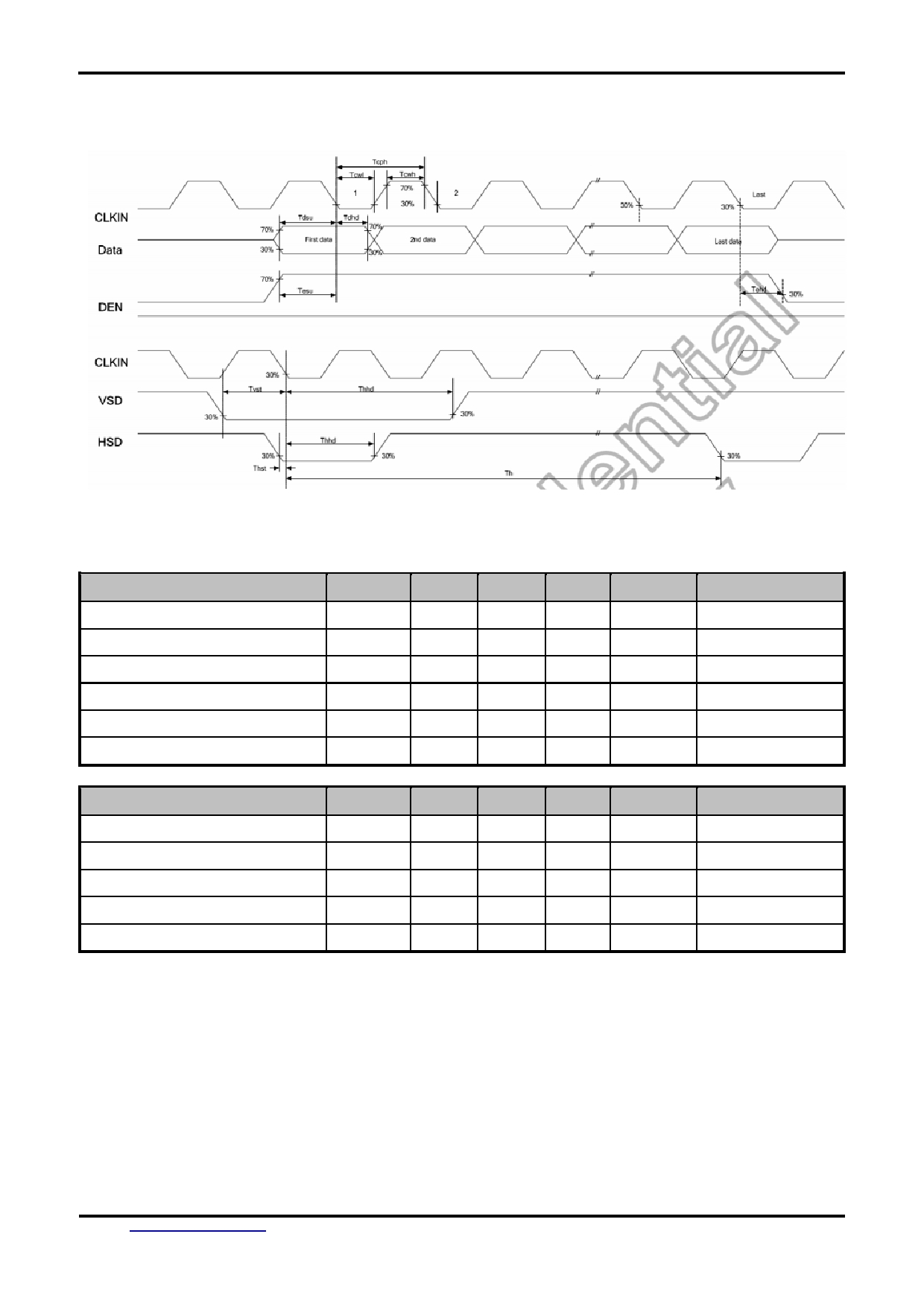

7.2

Input Clock and Data Timing Diagram

7.3

Timing

Item

Symbol

MIN.

TYP.

MAX.

Unit

Remark

Horizontal Display Area

thd

-

800

-

DCLK

DCLK Frequency

fclk

28

33.3

40

MHz

One Horizontal Line

th

862

1056

1200

DCLK

HS pulse width

thpw

1

-

40

DCLK

HS Blanking

thb

46

46

46

DCLK

HS Front Porch

thfp

16

210

354

DCLK

Item

Symbol

MIN.

TYP.

MAX.

Unit

Remark

Vertical Display Area

tvd

-

480

-

TH

VS period time

tv

513

525

650

TH

VS pulse width

tvpw

1

-

20

TH

VS Blanking

tvb

23

23

23

TH

VS Front Porch

tvfp

7

22

147

TH

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 8 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

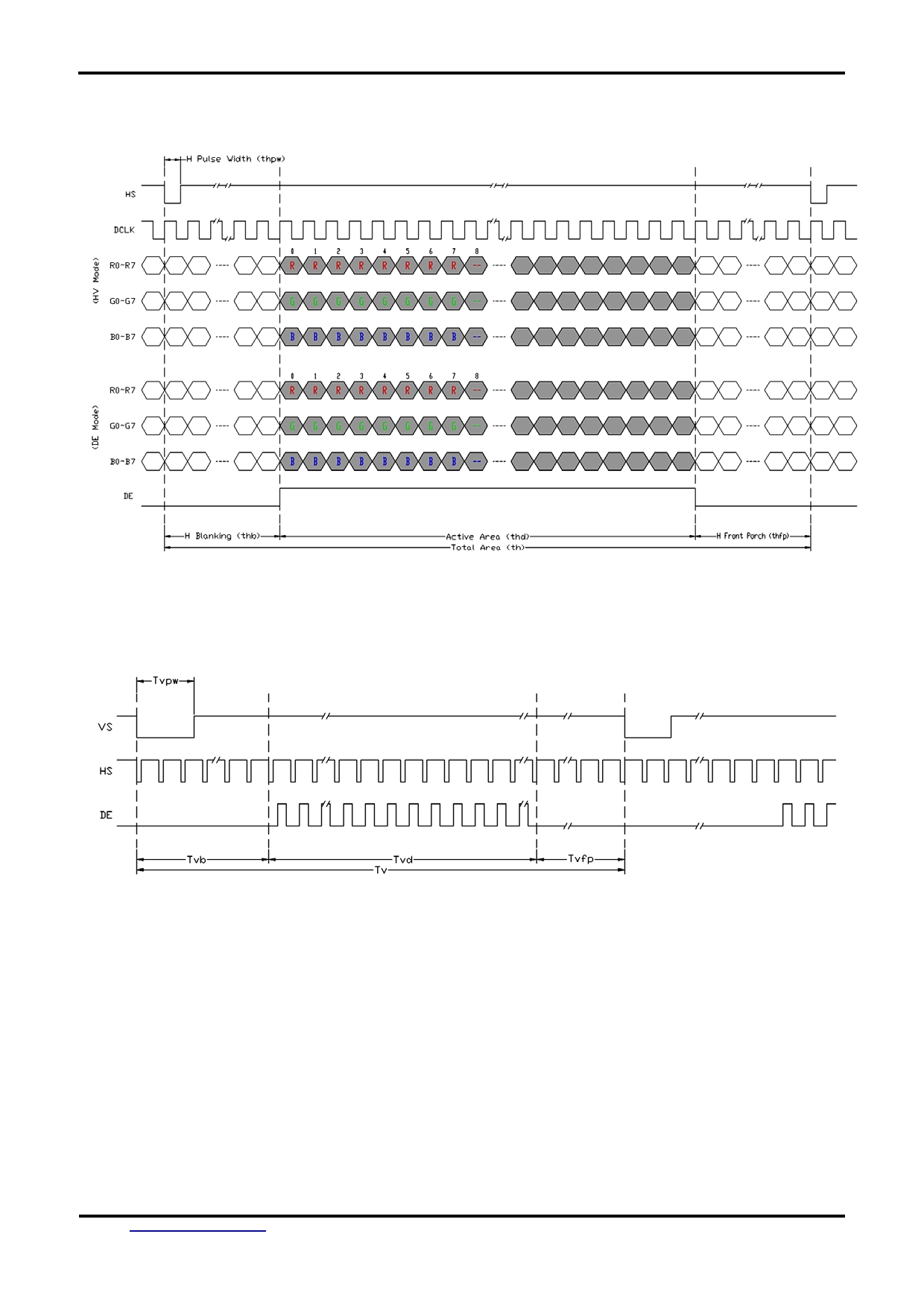

7.4

Data Input Format

Figure 6-2-1 Horizontal input timing diagram.

Figure 6-2-2 Vertical input timing diagram.

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 9 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

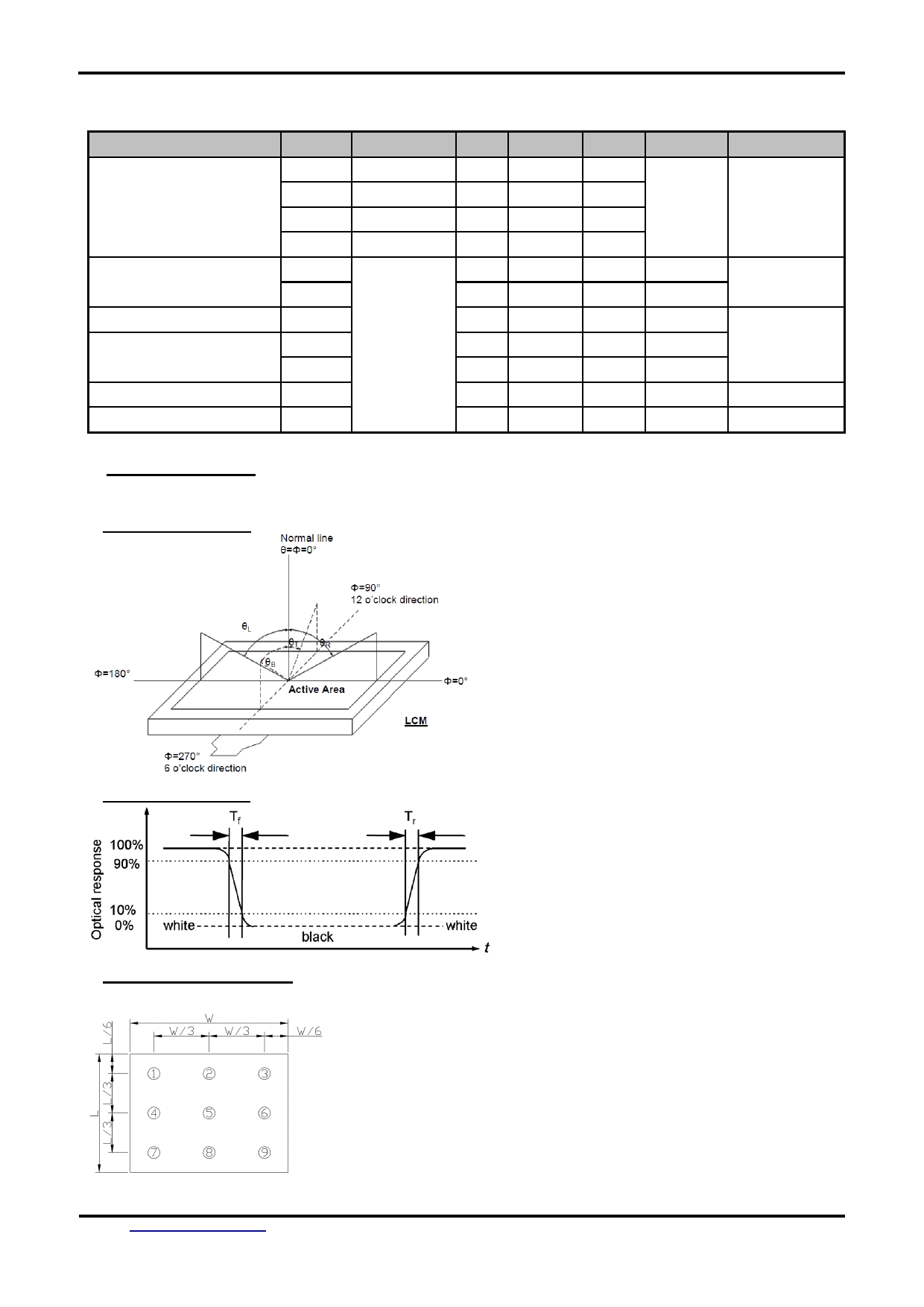

7.5

Optical Characteristics

Item

Symbol

Condition

MIN.

TYP.

MAX.

UNIT

Note.

θ L

9 o’clock

60

70

-

Viewing angle

θ R

3 o’clock

60

70

-

(CR¡Ý10)

degree

*2

θ T

12 o’clock

40

50

-

θ B

6 o’clock

60

70

-

T f

-

10

20

msec

Response Time

*3

T r

-

15

30

msec

Contrast ratio

CR

400

500

-

-

Normal

W X

0.26

0.31

0.26

-

*1

Color chromaticlty

θ =0 o

W Y

0.28

0.33

0.38

-

cd/m

2

Luminance

L

-

200

-

*4

Luminance uniformity

Y U

40

50

-

%

*4

Note:

*1. Definition of Contrast Ratio

The contrast ratio could be calculate by the following expression:

Contrast Ratio (CR) = Luminanc with all pixels white / Luminance with all pixels black

*2 Definition of Viewing Angle

*3 Definition of response time

*4 Definition of Luminance Uniformity

Luminance uniformity (Lu)=

Min. Luminance form pt1~pt9 / Max Luminance form Pt1~pt9

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 10 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

8. LCD Module Design and

8. Òº¾§ÏÔʾģ¿éÉè¼ÆºÍʹÓÃÐëÖª

Handling Precautions

- Please ensure V0, VCOM is adjustable, to enable LCD module get

-

Çë×¢ÒâV0, VCOM µÄÉ趨, ÒÔÈ·±£Òº¾§ÏÔʾģ¿éÔÚ²»Í¬

the best contrast ratio under different temperatures, view angles

µÄʹÓÃζÈÏÂÒÔ¼°ÔÚ²»Í¬µÄÊӽǺÍλÖù۲ìÄ£¿éÏÔ

and positions.

ʾ£¬¾ùÄÜ´ïµ½×î¼Ñ¶Ô±È¶È£¬ÇëÎñ±Ø½«Ó¦Óõç·ÉÏÉèÖÃ

- Normally display quality should be judged under the best contrast

Ϊ¶Ô±È¶È¿Éµ÷¡£

ratio within viewable area. Unexpected display pattern may com out

-

Çë×¢ÒâÒº¾§ÏÔʾģ¿éµÄÏÔʾƷÖÊÅж¨ÊÇÖ¸ÔÚÕý³£¶Ô±È

under abnormal contrast ratio.

¶ÈÏÂÒÔ¼°ÊÓ´°(V.A)·¶Î§ÄÚ½øÐеģ¬·ÇÕý³£¶Ô±È¶ÈÏÂÒº

- Never operate the LCD module exceed the absolute maximum

¾§¿ÉÄÜ»á³öÏÖ·ÇÔ¤ÆÚµÄÏÔʾ²»Á¼£¬Ó¦×¢ÒâÇø·Ö¡£

ratings.

-

ÇëÎðÔÚ×î´ó¶î¶¨ÖµÒÔÍâʹÓÃÒº¾§ÏÔʾģ¿é¡£

- Never apply signal to the LCD module without power supply.

- Keep signal line as short as possible to reduce external noise

-

ÇëÎðÔÚûÓнÓͨµçÔ´µÄÌõ¼þÏ£¬¸øÒº¾§ÏÔʾģ¿éÊäËÍ

interference.

Ðźš£

- IC chip (e.g. TAB or COG) is sensitive to light. Strong light might

-

Ç뾡¿ÉÄÜËõ¶ÌÐźÅÏßµÄÁ¬½Ó£¬ÒÔ±ÜÃâ¶ÔÒº¾§ÏÔʾģ¿é

cause malfunction. Light sealing structure casing is recommended.

µÄÐźŸÉÈÅ¡£

-

¼¯³Éµç·ÒòIC о Ƭ( ÈçTAB»òCOG)¶Ô×ÏÍâÏß¼«ÎªÃô

- Make sure there is enough space (with cushion) between case and

¸Ð£¬Ç¿¹â»·¾³Ï¿ÉÄÜ»áÒýÆðÒº¾§ÏÔʾģ¿é¹¦ÄÜʧЧ£¬

LCD panel, to prevent external force passed on to the panel;

otherwise that may cause damage to the LCD and degrade its

¹ÊÓ¦²ÉÓò»Í¸¹âµÄÍâ¿Ç¡£

display result.

-

ÇëÔÚÒº¾§ÏÔʾģ¿éÓëÍâ¿ÇÖ®¼ä±£Áô×ã¹»µÄ¿Õ¼

- Avoid showing a display pattern on screen for a long time

³Äµæ)£¬ÒÔ»º³åÍâÁ¦¶ÔÒº¾§ÏÔʾģ¿éµÄË𻵻òÒòÊÜÁ¦²»

(continuous ON segment).

¾ù¶ø²úÉúµÄÏÔʾ²»ÔȵÈÒì³£ÏÖÏó¡£

- LCD module reliability may be reduced by temperature shock.

-

±ÜÃâÒº¾§ÏÔʾÆÁÔÚijһ»-Ãæϳ¤Ê±¼äµãÁÁ£¬·ñÔòÓгö

- When storing and operating LCD module, avoids exposure to direct

sunlight, high humidity, high or low temperature. They may damage

ÏÖ²ÐÓ°µÄ·çÏÕ£»Çëͨ¹ýÈí¼þÿ¸ôÒ»¶Îʱ¼ä¸Ä±äÒ»´Î»-

or degrade the LCD module.

Ãæ¡£

- Never leave LCD module in extreme condition (max./min

-

Òº¾§ÏÔʾģ¿éµÄ¿É¿¿ÐÔ¿ÉÄÜÒòζȳå»÷¶ø½µµÍ¡£

storage/operate temperature) for more than 48hr.

-

ÇëÎðÔÚÑô¹âÖ±Éä¡¢¸ßʪ¡¢¸ßλòµÍÎÂÏ´¢´æºÍʹÓÃÒº

- Recommend LCD module storage conditions is 0 C~40 C

¾§ÏÔʾģ¿é£¬Õ⽫Ôì³ÉÒº¾§ÏÔʾģ¿éµÄË𻵻òʧЧ¡£

<80%RH.

- LCD module should be stored in the room without acid, alkali and

harmful gas.

-

ÇëÎðÔÚ¼«ÏÞ»·¾³(×î´ó/ ×îС´æ´¢/ ¹¤×÷ζÈ)ÏÂʹÓûò

- Avoid dropping & violent shocking during transportation, and no

excessive pressure press, moisture and sunlight.

- Òº¾§ÏÔʾģ¿é½¨Òé´æ´¢Ìõ¼þΪ:0 C ~40 C <80%RH¡£

- LCD module can be easily damaged by static electricity. Please

-

ÇëÎðÈÃÒº¾§ÏÔʾģ¿é´æ´¢ÓÚ´øÓÐ

ËáÐÔ,¼îÐ Ô, Óк¦Æø

maintain an optimum anti-static working environment to protect the

Ìå»·¾³Ö®ÖС£

LCD module. (eg. ground the soldering irons properly)

-

ÔÚÔËÊä¹ý³ÌÖÐ,ÇëÎðÈÃÒº¾§ÏÔʾģ¿éµøÂäÓëÃÍÁÒÕð¶¯,

- Be sure to ground the body when handling LCD module.

- Only hold LCD module by its sides. Never hold LCD module by

ͬʱ±ÜÃâ Òì³£¼·Ñ¹, ¸ßʪ¶È, ÓëÑô¹âÕÕÉä.

applying force on the heat seal or TAB.

-

Òº¾§ÏÔʾģ¿é¼«Ò×Êܾ²µçË𻵣¬ÇëÎñ±Ø±£Ö¤Òº¾§ÏÔʾ

- When soldering, control the temperature and duration avoid

Ä£¿éÔÚ·À¾²µçµÄ¹¤×÷»·¾³ÖÐʹÓûò±£´æ ¡£(Èç: ÀÓÌúÕý

damaging the backlight guide or diffuser which might degrade the

È·½ÓµØ,µÈ)

display result such as uneven display.

-

ÄÃÈ¡Òº¾§ÏÔʾģ¿éʱÐè×¢Òâ²Ù×÷ÈËÔ±µÄ½ÓµØÇé¿ö¡£

- Never let LCD module contact with corrosive liquids, which might

-

ÇëÊÖ³ÖÒº¾§ÏÔʾģ¿éµÄ±ßÑØÈ¡·ÅÄ£¿é£¬·ÀÖ¹ÈÈѹֽ»ò

cause damage to the backlight guide or the electric circuit of LCD

module.

TAB²¿Î»ÊÜÁ¦¡£

- Only clean LCD with a soft dry cloth, Isopropyl Alcohol or Ethyl

-

º¸½ÓÒº¾§Ä£¿éʱ£¬Çë×¢Òâ¿ØÖÆÀÓÌúµÄζȡ¢º¸½Óʱ

Alcohol. Other solvents (e.g. water) may damage the LCD.

¼ä£¬ÒÔÃâÌÌ»µµ¼¹â°å»òÆ«¹âƬ£¬µ¼ÖÂÏÔʾ²»ÔȵȲ»Á¼

- Never add force to components of LCD module. It may cause

ÏÖÏó·¢Éú¡£

invisible damage or degrade the module's reliability.

-

ÇëÎðʹÓÃÏ´°åË®µÈ¸¯Ê´ÐÔÒºÌå½Ó´¥Òº¾§Ä£¿é£¬ÒÔÃⸯ

- When mounting LCD module, please make sure it is free from

Ê´µ¼¹â°å»òÄ£¿éµç·¡£

twisting, warping and bending.

- Do not add excessive force on surface of LCD, which may cause

the display color change abnormally.

-

½ö¿ÉʹÓÃÈáÈíµÄ¸É²¼,Òì±û´¼»òÒÒ´¼Çå½àÒº¾§ÆÁ±í

- LCD panel is made with glass. Any mechanical shock (e.g.

Ã棬ÆäËûÈκÎÈܼÁ(Èç:Ë®)¶¼ÓпÉÄÜËð»µÒº¾§Ä£¿é¡£

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 11 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

dropping from high place) will damage the LCD module.

-

ÇëÎð¼·Ñ¹Òº¾§ÏÔʾģ¿éÉϵÄÔªÆ÷¼þ£¬ÒÔ±ÜÃâ²úÉúDZÔÚ

µÄË𻵻òʧЧ¶øÓ°Ïì²úÆ·¿É¿¿ÐÔ¡£

-

×°ÅäÒº¾§ÏÔʾģ¿éʱ£¬ÇëÎñ±Ø×¢Òâ±ÜÃâÒº¾§ÏÔʾģ¿é

µÄŤÇú»ò±äÐΡ£

-

ÇëÎð¼·Ñ¹Òº¾§ÏÔʾÆÁ±íÃ棬Õ⽫µ¼ÖÂÏÔʾÑÕÉ«µÄÒì

³£¡£

-

Òº¾§ÆÁÓɲ£Á§ÖÆ×÷¶ø³É£¬ÈκλúеÅöײ(Èç´Ó¸ß´¦µø

Âä)¾ùÓпÉÄÜËð»µÒº¾§ÏÔʾģ¿é¡£

- Protective film is attached on LCD screen. Be careful when peeling

-

Òº¾§ÆÁ±íÃæ´øÓб£»¤Ä¤, ½Ò³ý±£»¤Ä¤Ê±ÐèҪעÒâ¿ÉÄÜ

off this protective film, since static electricity may be generated.

²úÉúµÄ¾²µç¡£

- Polarizer on LCD gets scratched easily. If possible, do not remove

-

ÒòÒº¾§ÏÔʾÆÁ±íÃæµÄÆ«¹âƬ¼«Ò×»®ÉË£¬°²×°Íê³É֮ǰ

LCD protective film until the last step of installation.

Ç뾡Á¿²»Òª½Òϱ£»¤Ä¤¡£

- When peeling off protective film from LCD, static charge may cause

-

Ç뻺Âý½Ò³ý±£»¤Ä¤£¬Ôڴ˹ý³ÌÖÐÒº¾§ÏÔʾÆÁÉÏ¿ÉÄÜ»á

abnormal display pattern. The symptom is normal, and it will turn

²úÉú¾²µçÏߣ¬´ËΪÕý³£Çé¿ö£¬¿ÉÔÚ¶Ìʱ¼äÄÚÏûʧ¡£

back to normal in a short while.

- LCD panel has sharp edges, please handle with care.

-

Çë×¢Òâ±ÜÃâ±»Òº¾§ÏÔʾÆÁµÄ±ßÔµ¸îÉË¡£

- Never attempt to disassemble or rework LCD module.

-

Çë²»ÒªÊÔͼ²ðж»ò¸ÄÔìÒº¾§ÏÔʾģ¿é¡£

- If display panel is damaged and liquid crystal substance leaks out,

-

µ±Òº¾§ÏÔʾÆÁ³öÏÖÆÆÁÑ,ÄÚ²¿Òº¾§ÒºÌå¿ÉÄÜÁ÷³ö;

be sure not to get any in your mouth, if the substance comes into

¹ØÒºÌå²»¿ÉÍ̳Ô, ¾ø¶Ô²»¿É½Ó´¥×ì°Í, Èç½Ó´¥µ½Æ¤·ô

contact with your skin or clothes promptly wash it off using soap

»òÒ·þ, ÇëʹÓ÷ÊÔíÓëÇåË®³¹µ×ÇåÏ´.

and water.

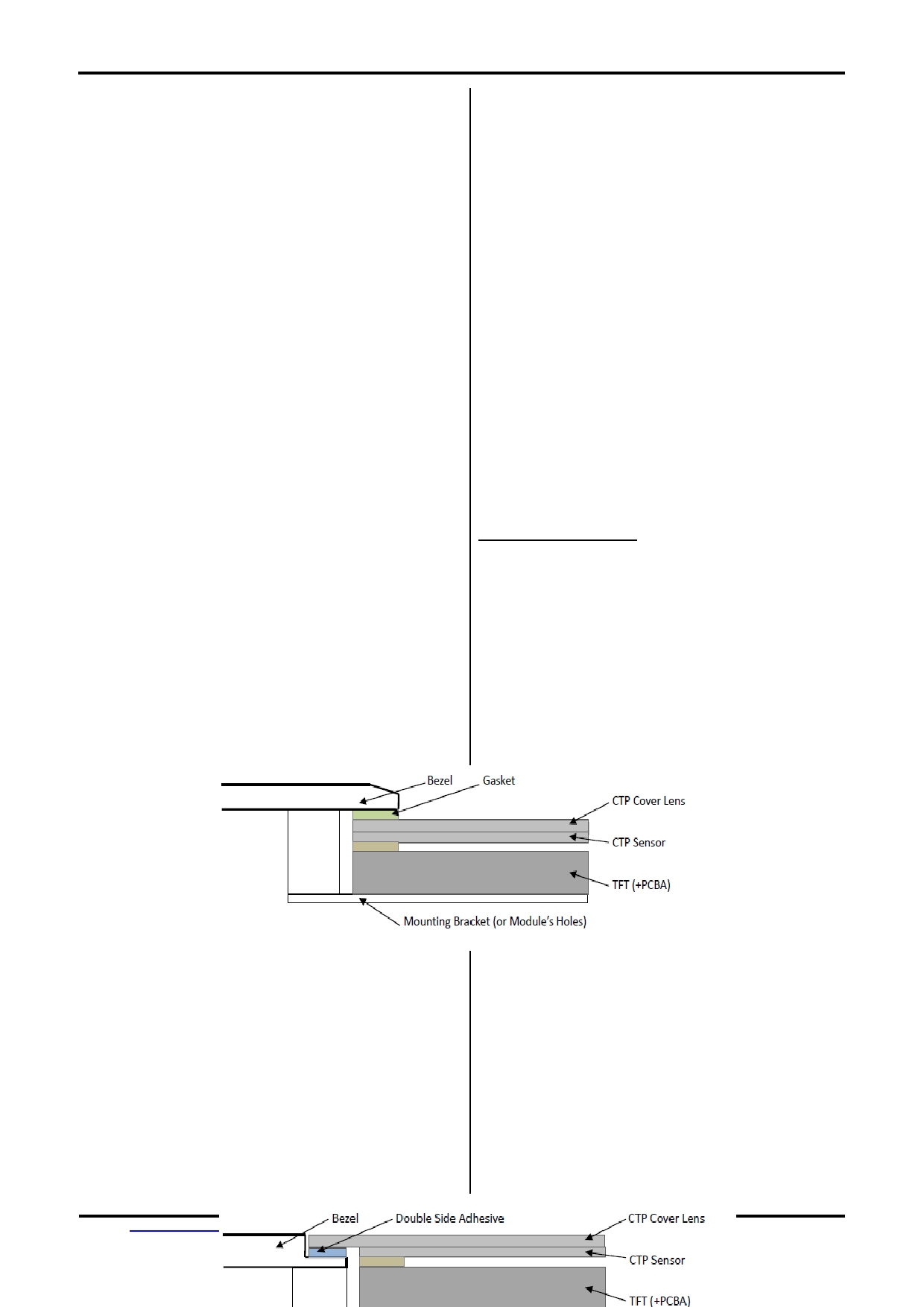

9. CTP Mounting Instructions

9. µçÈÝ´¥ÃþÆÁ°²×° Ö¸µ¼

9.1 Ãæ¿ò°²×°£¨¸½Í¼

1£©

9.1 Bezel Mounting (Figure 1)

-

¿Í»§Ãæ¿ò´°¿ÚÓ¦´óÓÚCTP¶¯×÷ÇøÓò£¬¸÷±ßÀ붯×÷ÇøÓ¦

- The bezel window should be bigger than the CTP active area. It

¡Ý0.5mm.

should be¡Ý0.5mm each side.

-

Ãæ¿òÓëCTPÃæ°å¼äÓ¦µæÓнºµæ£¬Æä×îÖÕ¼ä϶ԼΪ0.5¡«

- Gasket should be installed between the bezel and the CTP surface.

1.0mm.

The final gap should be about 0.5~1.0mm.

-

½¨Òé±ØҪʱÔÚ±³ÃæÌṩ¸½¼ÓÖ§¼Ü(ÀýÈçÎÞ°²×°½á¹¹µÄ±¡

- It is recommended to provide an additional support bracket for

ÐÍ TFTÄ£¿é)£¬Ó¦½öÀûÓÃÊʵ±Ö§³ÅÒÔ±£³ÖÄ£¿éλÖÃ.

backside support when necessary (e.g. slim type TFT module

without mounding structure). They should only provide appropriate

support and keep the module in place.

-

°²×°½á¹¹Ó¦¾ßÓÐ×ã¹»µÄÇ¿¶È£¬ÒÔ·ÀÖ¹Íⲿ²»¾ùÔÈÁ¦»ò

- The mounting structure should be strong enough to prevent

ŤÇúÁ¦×÷Óõ½Ä£¿éÉÏ.

external uneven force or twist act onto the module.

Figure 1

9.2 Surface Mounting (Figure 2)

9.2 ǶÈë°²×°£¨¸½Í¼

2£©

- As the CTP assembling on the countersink area with double side

-

¿Í»§Ãæ¿òÓ¦¾ßÓÐʹÓÃË«Ã潺ճÌùCTPµÄ½á¹¹³Ą́Ã棬

adhesive.

ÆäÕ³ÌùÃæÒªÇóƽÕûÇҽྻÎÞÎÛÒÔ±£Ö¤Õ³ÌùÀο¿.

The countersink area should be flat and clean to ensure the double

side adhesive installation result.

- The Bezel is recommend to keep a gap (¡Ý 0.3mm each side)

-

¿¼Âǵ½ÖÆ×÷Îó²î£¬½¨ÒéÃæ¿òÓëCTP¸Ç°åÖ®¼äËÄÖÜÁôÓÐ

around the cover lens for tolerance.

¡Ý0.3mm¼ä϶.

- It is recommended to provide an additional support bracket with

-

½¨Òé±ØҪʱÔÚ±³ÃæÌṩµæÓнºµæ¸½¼ÓÖ§¼Ü(

gasket for backside support when necessary (e.g. TFT module

½á¹¹µÄTFTÄ£¿é)£¬Ó¦½öÀûÓÃÊʵ±Ö§³ÅÒÔ±£³ÖÄ£¿éλ

without mounding structure). They should only provide appropriate

ÖÃ.

support and keep the module in place.

- The mounting structure should be strong enough to prevent

-

°²×°½á¹¹Ó¦¾ßÓÐ×ã¹»µÄÇ¿¶È£¬ÒÔ·ÀÖ¹Íⲿ²»¾ùÔÈÁ¦»ò

external uneven force or twist act onto the module

ŤÇúÁ¦×÷Óõ½Ä£¿éÉÏ¡£

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 12 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

Figure 2

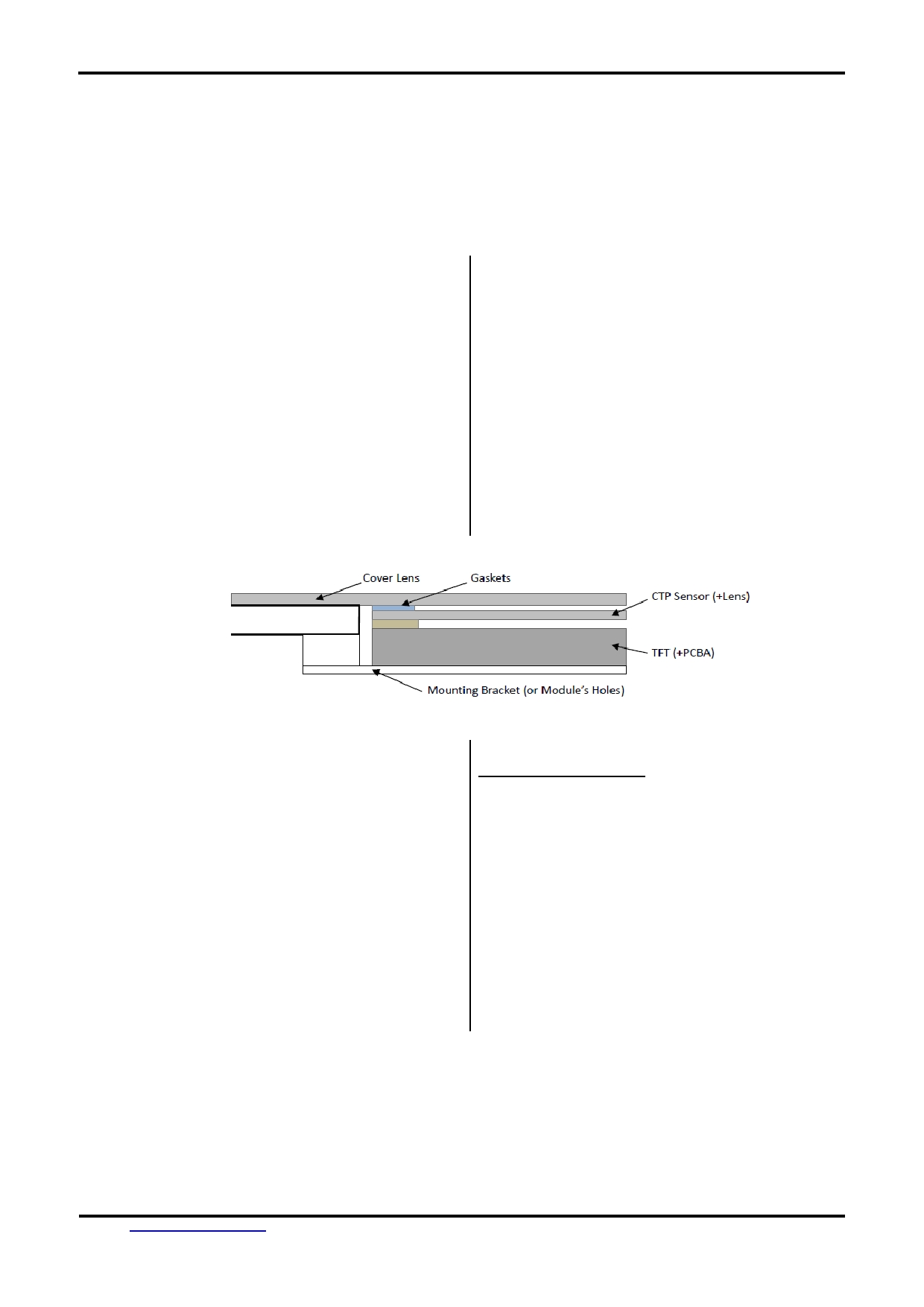

9.3 Additional Cover Lens Mounting (Figure 3)

9.3 ¸²¼Ó¸Ç°å£¨¸½Í¼

3£©

- For the case of additional cover Lens mounting, it is necessary to

-

ÐèÒª¸²¼Ó²£Á§¸Ç°åµÄ°²×°£¬ÎªÈ·±£Æ书ÄÜ£¬ÓбØÒª²é

recheck with the CTP specification about the material and thickness

¿´²úÆ·¹æ¸ñÊéÖÐÓйظǰå²ÄÁϺͺñ¶ÈµÄ˵Ã÷.

to ensure the functionality.

- It should keep a 0.2~0.3mm gap between the cover lens and the

-

²£Á§¸Ç°åÓëCTP±íÃæÖ®¼äÓ¦ÁôÓÐ0.2¡«0. 3mm¼ä϶.

CTP surface..

- The cover lens window should be bigger than the active area of the

-

²£Á§¸Ç°åÊÓ´°Ó¦´óÓÚCTP¶¯×÷ÇøÓò£¬¸÷±ßÀ붯×÷ÇøÓ¦

CTP.It should be¡Ý0.5mm each side.

¡Ý0.5mm¡£

- It is recommended to provide an additional support bracket for

-

½¨Òé±ØҪʱÔÚ±³ÃæÌṩ¸½¼ÓÖ§¼Ü(ÀýÈçÎÞ°²×°½á¹¹µÄ±¡

backside support when necessary (e.g. slim type TFT module

ÐÍ TFTÄ£¿é)£¬Ó¦½öÀûÓÃÊʵ±Ö§³ÅÒÔ±£³ÖÄ£¿éλÖÃ.

without mounding structure). They should only provide appropriate

support and keep the module in place.

- The mounting structure should be strong enough to prevent

-

°²×°½á¹¹Ó¦¾ßÓÐ×ã¹»µÄÇ¿¶È£¬ÒÔ·ÀÖ¹Íⲿ²»¾ùÔÈÁ¦»ò

external uneven force or twist act onto the module.

ŤÇúÁ¦×÷Óõ½Ä£¿éÉÏ.

Figure 3

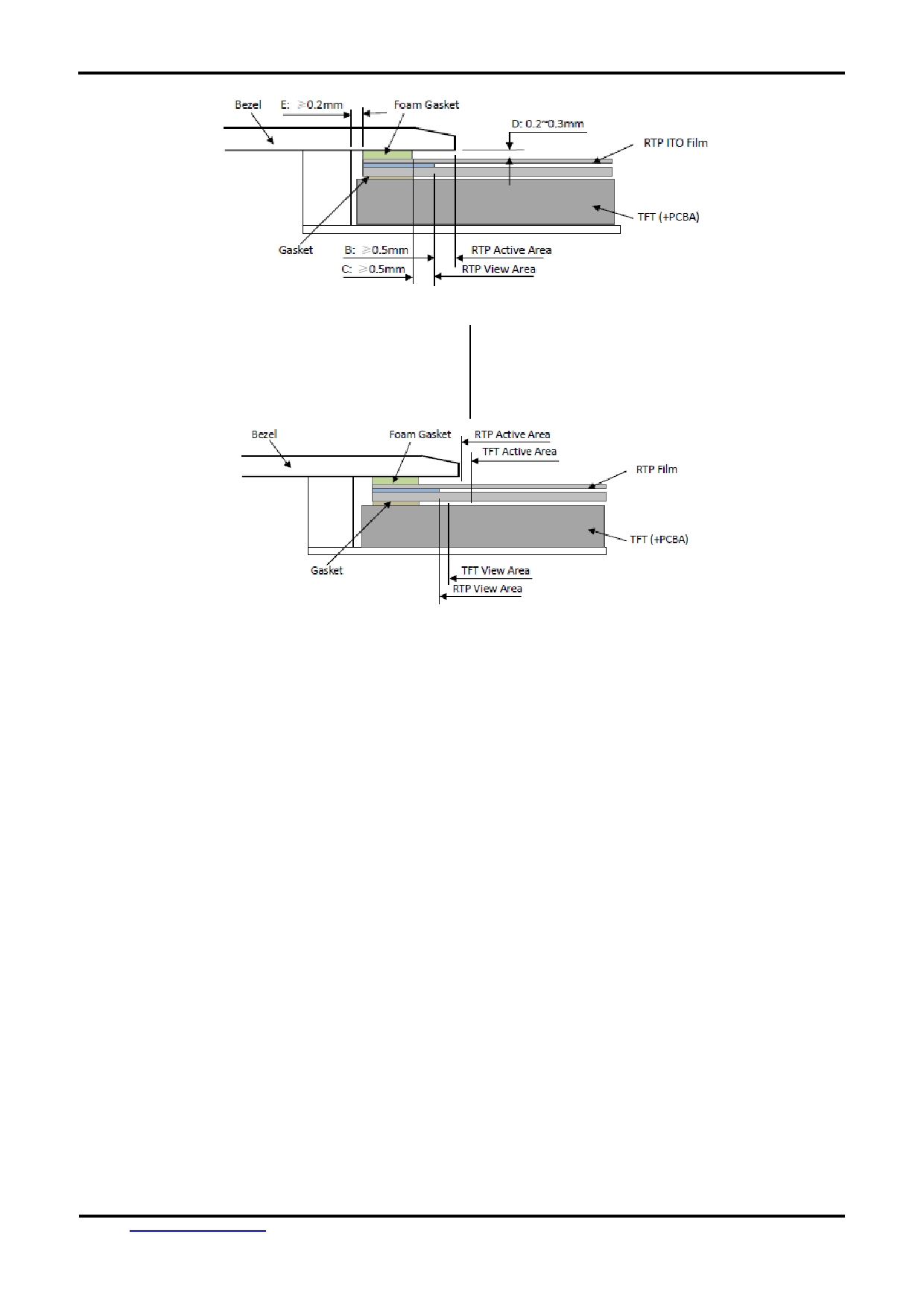

10. RTP Mounting Instructions

10. µç×è´¥ÃþÆÁ°²×°Ö¸µ¼

- Ϊ±ÜÃâÃæ¿òÖ±½ÓѹÔÚ¶¯×÷Çø(A.A.)ÉÏÔì³ÉÎó¶¯×÷£¬Ãæ¿ò

- It should bezel touching the RTP Active Area (A.A.) to prevent

Óëµç×è´¥ÃþÆÁ(RTP)Ö®¼äÓ¦ÁôÓÐÒ»¶¨µÄ¿Õ϶

abnormal touch.It should left gab D=0.2~0.3mm in between.

D=0.2~0.3mmÖ®¼ ä.( ¸½Í¼4)

(Figure 4)

- Outer bezel design should take care about the area outside the

- Éè¼ÆÃæ¿òʱ£¬Òª×¢ÒâÓÃÃæ¿ò±£»¤´¥ÃþÆÁËÄÖܵķDZ£Ö¤²Ù

A.A. Those areas contain circuit wires which is having different

×÷ÇøÓò£¬ÒòΪ²¼ÏßÇøÓòÔÚ´Ë´¦ÐγÉһ̨½×£¬ÔÚ´ËÇøÓò

thickness. Touching those areas could de-form the ITO film. As a

¸½½ü²Ù×÷ʱ ITO Film

±äÐνϴó£¬ÈÝÒ×µ¼Ö ITO Ë𻵶ø

result bezel the ITO film be damaged and shorten its lifetime.

½µµÍÊÙÃü¡£Îª±£»¤

RTPºÍ±ÜÃâÎó²Ù×÷£¬ÔÚ

RTP ÓëÃæ¿ò

It is suggested to protect those areas with gasket (between the

Ö®¼äµæ»º³åÎG asket £©£¬ÎÒÃǽ¨ÒéÉè¼ÆÃæ¿òÓ¦¸²¸Ç

bezel and RTP).The suggested figures are B ≥0.50mm; C≥0.50mm .

¶¯×÷ÇøµÄ±ßÔµ£¬Ãæ¿ò±ßÔµµ½V.A.ÇøµÄ¾àÀë B¡Ý0.50mm;

(Figure 4)

µæȦÄÚ±ßÔµµ½V.A.ÇøµÄ¾àÀë C¡Ý0.50mm . ( ¸½Í¼ 4)

- The bezel side wall should keep space E= 0.2 ~ 0.3mm from the

- ÔÚÉè¼ÆÃæ¿òÓëRTP ×éװʱ£¬Ó¦¿¼Âǵ½Ãæ¿òÄÚ²àÓëRTP Íâ

RTP. (Figure 4)

²àµÄ¼ä¾àE¡Ý0.2mm.

( ¸½Í¼ 4)

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 13 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

Figure 4

- In general design,

- ͨ³£Éè¼Æʱ£º

RTP V.A. should be bigger than the TFT V.A.

RTPµÄ¿ÉÊÓÇø V.A.

Ó¦²»Ð¡ÓÚ TFT µÄ¿ÉÊÓÇø V.A.

and RTP A.A. should be bigger than the TFT A.A.

¼° RTP µÄ¶¯×÷Çø A.A.

Ó¦²»Ð¡ÓÚ TFT µÄ¶¯×÷Çø A.A.

(Figure 5)

( ¸½Í¼ 5)

Figure 5

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 14 of 15

TOPWAY

LCD Module User Manual

LMT070DNCFWD-NNA

Warranty

This product has been manufactured to our company’s specifications as a part for use in your company’s general

electronic products. It is guaranteed to perform according to delivery specifications. For any other use apart from general

electronic equipment, we cannot take responsibility if the product is used in medical devices, nuclear power control

equipment, aerospace equipment, fire and security systems, or any other applications in which there is a direct risk to

human life and where extremely high levels of reliability are required. If the product is to be used in any of the above

applications, we will need to enter into a separate product liability agreement.

-

We cannot accept responsibility for any defect, which may arise form additional manufacturing of the product

(including disassembly and reassembly), after product delivery.

-

We cannot accept responsibility for any defect, which may arise after the application of strong external force to the

product.

-

We cannot accept responsibility for any defect, which may arise due to the application of static electricity after the

product has passed our company’s acceptance inspection procedures.

-

When the product is in CCFL models, CCFL service life and brightness will vary according to the performance of the

inverter used, leaks, etc. We cannot accept responsibility for product performance, reliability, or defect, which may

arise.

-

We cannot accept responsibility for intellectual property of a third part, which may arise through the application of our

product to our assembly with exception to those issues relating directly to the structure or method of manufacturing of

our product.

Document Name: LMT070DNCFWD-NNA-Manual-Rev0.1.DOC

Page: 15 of 15