Smarter Coffee Roasting Control with Topway Smart TFT LCDs

In the world of specialty coffee, consistency and control are key. Every bean, every batch, and every roast profile matters. Traditional industrial HMIs can deliver the functionality roasters need, but they often come with high hardware, integration, and maintenance expenses. That’s where the Topway HMT070EMC-C (7") and HMT101AMC-C (10.1") Smart TFT LCDs step in—offering a modern, cost-effective solution without compromising performance.

Why Smart TFT for Coffee Roasters?

A Smart TFT LCD is not just a display; it's a complete control solution. Both the HMT101AMC-C and HMT070EMC-C models comes with a 32-bit ARM MCU on board, a graphics engine, and a touch panel. This means the display can handle graphics and user interactions on its own, offloading that work from the host controller. Free UI design tool enables drag-and-drop coffee roaster control screen design, no code needed.

Precise Control and Data Visualization

Coffee roasting is both a science and an art. Subtle changes in parameters such as temperature, time, airflow, and heat can significantly impact the coffee bean's flavor. Traditional roasters often rely on experience and manual adjustments, making precise control and data recording difficult. Traditional industrial HMI can provide precise control and data visualization, but with substantial cost. The introduction of Smart TFT display modules has completely changed this situation.

Through the built-in RS485 Modbus RTU interface, Smart TFT display modules can seamlessly connect to various sensors and actuators within the roaster. This means roasters can obtain real-time data on bean temperature, exhaust temperature, ambient temperature, airflow opening, heat intensity, and other critical parameters, and present them graphically on a high-definition, colorful TFT screen. For example, roasting curves can be plotted and displayed in real-time on the screen, allowing roasters to clearly see the temperature trend over time, thereby precisely controlling the roasting process. This unprecedented data visualization capability gives roasters an "all-seeing eye," enabling them to observe every detail during the roasting process and providing solid data support for replicating ideal flavors.

Automated Roasting and Lua Script Engine

For roasters pursuing efficiency and consistency, automation is key to improving productivity. Farewell to tedium, embrace Intelligence, the Lua script engine built into Smart TFT display modules brings unlimited possibilities for automation in coffee roasting equipment. Roasters can pre-set different roasting profiles for coffee beans from different origins or with different processing methods.

Once roasting process started, the display module with Lua script can automatically control various parameters of the roaster according to the pre-set profile, achieving fully automated roasting. This means roasters no longer need to constantly monitor the machine for manual adjustments, greatly reducing the operational burden while ensuring the consistency of each batch of roasted coffee beans. Whether a novice or an experienced roasting master, anyone can easily achieve professional-grade automated roasting with simple operations, allowing them to devote more energy to exploring and innovating coffee flavors.

Features Tailored for Coffee Roasters

- Real-time roasting curve display for bean and environmental temperatures. The HMT101AMC-C offers a large 10.1-inch screen with a resolution of 1024x600 pixels, while the HMT070EMC-C provides a compact 7.0-inch display with the same resolution. Both provide a crisp, clear display for monitoring complex data.

- Profile management: load, save, and execute roast profiles directly within the screen.

- Alarm notifications for over-temperature or maintenance alerts.

- Multi-language UI for international operations.

- Rugged Design: The modules have a wide operating temperature range of -20°C to +70°C, making them suitable for the fluctuating temperatures near a coffee roaster.

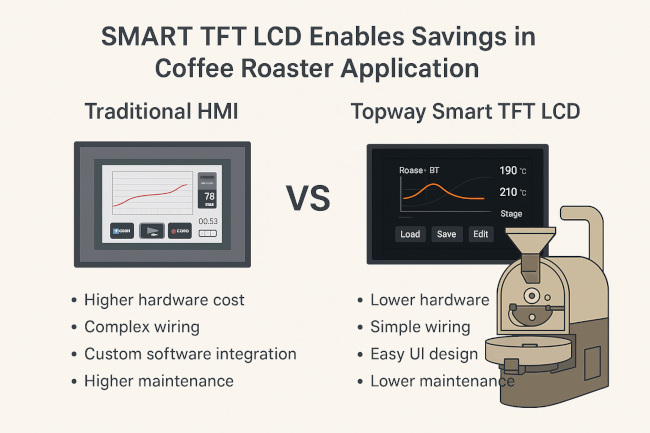

Cost Savings Over Traditional HMIs

- Lower hardware costs – No need for a separate industrial HMI panel and PLC display driver; Smart TFT combines both.

- Reduced wiring and installation labor – RS485 Modbus RTU allows direct bus connection to controllers and sensors, cutting down on complex cabling.

- Faster development – Using TOPWAY SGTools, UI screens and control logic can be pre-designed and loaded via USB or U-disk, eliminating costly custom software integration.

- Scalable without licensing fees – Unlike many PLC-HMI systems, there are no additional per-device software costs.

- Lower maintenance – Fewer components mean fewer failure points and simplified servicing.

A Perfect Fit for Specialty and Commercial Roasters

From small-batch artisan roasting machines to high-volume industrial lines, the HMT070EMC-C and HMT101AMC-C deliver the intuitive touch interface, graphical roasting data, and precise process control you need—at a fraction of the price of traditional systems.

For coffee roasting equipment manufacturers, integrating Smart TFT display modules means that their products will be more competitive and better able to meet the demand of modern coffee enthusiasts and professional roasters for smart, efficient, and convenient roasting experiences.