Elevating Power Quality Monitoring: The Advantage of Smart TFT LCDs

The modern industrial landscape relies heavily on robust electrical systems, making Power Quality Monitors (PQMs) indispensable tools. These devices ensure the stability, efficiency, and safety of power grids and industrial machinery. However, the true value of a PQM lies in its Human-Machine Interface (HMI) – the window into complex electrical data. As Industry 4.0 drives demand for real-time processing and edge intelligence, traditional HMIs often fall short, posing significant design challenges for engineers.

Design engineers face the dual challenge of developing intuitive, data-rich interfaces while ensuring the underlying hardware is rugged, reliable, and cost-effective. This post introduces Topway Smart TFT LCDs as the intelligent, integrated solution designed to meet these evolving demands, simplifying development and enhancing performance for next-generation PQM applications.

The Intelligence Within: Unpacking Topway Smart TFT LCD Technology

Integrated Processing Power for Edge Intelligence

Topway Smart TFT LCDs are more than just displays; they are intelligent HMI modules featuring an on-board 32-bit Microcontroller Unit (MCU) and a dedicated graphics engine. This integration is a pivotal advancement for industrial applications like PQMs, where real-time data processing is paramount.

Power Quality Monitors generate vast amounts of real-time data, including complex waveforms, harmonics, and transients. Traditionally, the host MCU would be burdened with both processing this raw electrical data and rendering the graphical interface. By embedding a powerful 32-bit MCU and a dedicated graphics engine directly onto the Smart TFT LCD module, Topway offloads the display processing workload from the main system controller. This allows the display to handle graphical rendering and even some data pre-processing locally, effectively bringing intelligence closer to the data source within the HMI. The result is faster display updates, smoother animations, and a more responsive user experience, all while freeing up the host MCU to focus on its primary task of high-speed power quality measurement and analysis. This approach aligns with the concept of embedded analytics by providing immediate, in-context information without requiring the main system to constantly push pixel data.

Accelerated Development Ecosystem for Rapid Innovation

Topway significantly streamlines the HMI development process with its comprehensive software tools. A standout feature is the Graphical UI Editor - SGTools, which promotes a "zero-coding" approach to HMI construction. Design engineers can simply drag and drop elements, configure properties, and build complex interfaces without writing extensive display code. The inclusion of a built-in Lua Script language engine, particularly in models like the HMT070ETA-D, further empowers the creation of rich and dynamic user interfaces, offering flexibility for custom logic and animations.

In today's competitive market, rapid product development and deployment are crucial. Traditional display integration often involves painstaking low-level graphics programming, which is time-consuming, error-prone, and requires specialized expertise. Topway's approach fundamentally changes this by providing a graphical UI editor and high-level programming capabilities. This abstraction allows design engineers to focus on the overall user experience and application logic rather than the intricacies of pixel manipulation. By enabling a "zero-coding" design environment for the HMI, Topway drastically cuts down on development cycles, allowing companies to bring their PQM products to market faster and respond more agilely to evolving customer needs. This directly contributes to cost savings and a stronger competitive position.

Seamless Communication & Robust Data Management

Topway Smart TFT LCDs offer reliable communication interfaces crucial for industrial integration. Smart TFT LCDs utilize RS-485, RS-232 interfaces for real-time control and data exchange with the host. This widely adopted serial standard ensures robust point-to-point communication.

USB interfaces are provided for convenient project download, allowing for easy preloading of UI design files and image assets. This functions like a standard "USB-drive," simplifying firmware updates and content management. The modules manage data efficiently with Flash Memory for storing design files, pictures, and icons, and RAM for real-time "VP variables" that can be accessed and updated by the host. This architecture supports dynamic display content.

Design engineers frequently encounter diverse communication requirements in industrial settings, often needing to integrate with existing control systems or network architectures. While the chosen Smart TFT LCDs for PQM applications, HMT043BMC-1C, HMT070ETA-D and HKT101AMC-C, offer highly reliable RS-485 and RS-232C interfaces for their robust and widely adopted serial communication, it is important for engineers to recognize Topway's broader commitment to industrial connectivity. The company's Smart LCD product line supports a wider array of standard industrial interfaces, including RJ45 for IoT applications, CAN bus for robust performance in harsh environments, and RS485 for long-distance communication. This comprehensive offering signals Topway's versatility and ability to cater to various PQM system designs, assuring engineers of potential scalability or alternative solutions for future projects, even if these specific models highlighted here do not feature all of them.

Precision at Your Fingertips: Smart LCDs for Power Quality Monitoring

Real-time Visualization of Complex Data

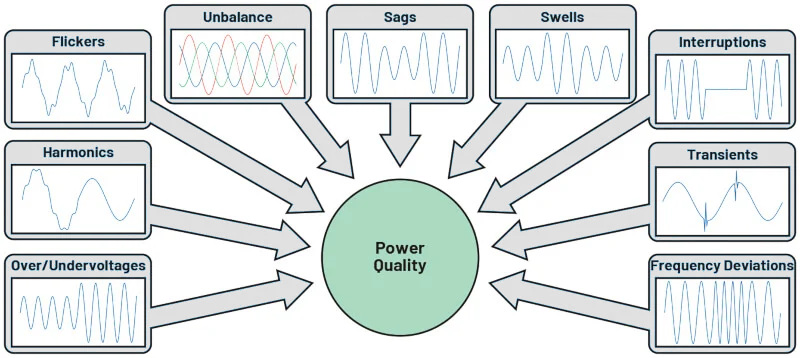

PQMs are sophisticated instruments that measure a wide array of electrical parameters, including voltage, current, active/reactive power, power factor, energy consumption, harmonics (up to 50th order), transients, flicker, and inrush current. Displaying this dynamic, high-fidelity data clearly and instantly is non-negotiable for effective monitoring and troubleshooting.

Topway Smart LCDs, with their integrated graphics engines and efficient data management , excel at presenting these complex measurements in real-time. This enables operators to quickly identify trends, detect anomalies like voltage/current imbalance, and respond to critical events with electronic alarm notifications. Take a look at below demo, presenting complex data on Smart TFT LCD is quick and easy.

Power quality issues, such as transients and harmonics, are often fleeting but can cause significant damage or inefficiency. For a PQM to be effective, its HMI must be able to display these events as they happen, allowing operators to react promptly. The Smart LCD's integrated graphics engine is specifically designed for efficient rendering of dynamic content, while the VP variables in RAM provide a rapid conduit for real-time data updates from the host. This architecture ensures that the high-speed, high-resolution data captured by the PQM's sensors can be translated into clear, actionable visualizations without lag, directly supporting faster decision-making and problem-solving in critical industrial environments.

Rugged Reliability for Industrial Demands

Industrial environments are inherently challenging, characterized by extreme temperatures, dust, moisture, and vibration. PQMs, often deployed in control panels, factories, or even outdoor substations, require HMIs that can withstand these harsh conditions for years of continuous operation.

Topway Smart TFT LCDs are designed with this in mind, offering an impressive operating temperature range of -20°C to +70°C. They are built with quality components for durability, ensuring reliable performance and minimizing maintenance costs. Features like robust design for operational vibrations and suitability for embedded mounting further enhance their resilience.

Design engineers must select components that can reliably operate within the environmental conditions of the PQM's deployment. Industrial HMIs are expected to function in diverse settings, from heated control rooms to unconditioned factory floors, where temperatures can vary significantly, and exposure to dust, moisture, and vibration is common. The HMT043BMC-1C and HKT070DMC-2C models both specify an operating temperature range of -20°C to +70°C. This range aligns well with the definition of "Rugged HMIs" (typically -30°C to +70°C), indicating their suitability for a vast majority of industrial applications. However, for niche applications in extremely cold climates (e.g., -40°C in Canada/Scandinavia), engineers would need to consider additional environmental conditioning or more specialized displays, ensuring that the modules' robust, yet not universally extreme, capabilities are accurately understood.

Intuitive User Experience

A PQM's HMI must be intuitive, allowing operators to quickly interpret complex data and interact efficiently, even while wearing gloves. The ability to display warnings and change indicator colors based on power quality events is crucial for safety and operational efficiency.

Topway Smart LCDs offer capacitive touch panels (HMT070ETA-D), providing a modern, highly responsive, and durable user interface. This, combined with the ability to design custom user interfaces via the SGTools, ensures an optimal viewing and interaction experience from various angles.

In industrial environments, human-machine interaction needs to be seamless and reliable, even under challenging conditions. Operators frequently wear protective gloves, which can hinder the responsiveness of traditional capacitive touchscreens. The HMT070ETA-D's capacitive touch technology offers superior sensitivity and multi-touch capabilities, directly addressing the need for "high touch sensitivity with various types of gloves". This feature, combined with the ability to create highly customizable and visually clear interfaces using the UI editor, ensures that PQM operators can interact with the system efficiently and accurately, reducing operational errors and improving overall productivity and safety.

Optimizing Design Cycles and Costs

By integrating the MCU and graphics engine into the display module, Topway Smart LCDs significantly reduce the workload on the host main board. This can lead to simpler, lower-cost main board designs. The simplified development process, enabled by the graphical UI editor and high-level programming, directly translates to accelerated time-to-market and cost-effectiveness. Engineers can prototype and iterate designs much faster, reducing overall development expenses. Furthermore, the inherent durability and reliability of these industrial-grade displays contribute to reduced maintenance costs and a longer product lifecycle.

Tailored Solutions: Topway Smart TFT LCDs for Every PQM Application

Topway offers a range of Smart TFT LCDs, two of which are particularly well-suited for power quality monitoring applications due to their balance of size, features, and performance.

Compact Power: The HMT043BMC-1C

For applications requiring a small footprint and essential HMI capabilities, the HMT043BMC-1C is an excellent choice. This 4.3-inch Smart TFT Module features a crisp 480x272 resolution. It comes with a 32-bit MCU and graphics engine, supporting TOPWAY SGTools for efficient interface design. Communication is handled via RS-485 and USB. Its compact dimensions (121.9 x 74.7 x 14.1 mm max) and robust -20°C to +70°C operating temperature make it ideal for embedded industrial control, instrumentation, and power electric equipment applications where space is at a premium.

Enhanced Clarity: The HMT070ETA-D

When a larger, more detailed display is required for comprehensive data visualization, the HMT070ETA-D steps up. This 7.0-inch Smart TFT Display boasts a higher 1024x600 resolution, providing ample screen real estate for complex graphs, multiple parameters, and detailed event logs. It features a Capacitive Touch Panel, offering a modern, highly responsive, and durable user interface. Beyond the integrated MCU and graphics engine, the HMT070ETA-D includes a Lua script engine for advanced customizability and a generous 256MB flash memory for storing extensive UI assets and data. Like its smaller counterpart, it supports RS-232C and USB communication and operates reliably across the -20°C to +70°C industrial temperature range. Its larger active area (154.21 x 85.92 mm) and full viewing direction are perfect for detailed power quality analysis.

Empowering the Engineer: Practical Advantages of Topway Smart LCDs

Simplified Integration and Reduced Host MCU Burden

The integrated MCU and graphics engine within Topway Smart LCDs fundamentally shift the HMI development paradigm. Instead of the host microcontroller managing complex display refresh rates and pixel-level rendering, it communicates with the Smart LCD using simple serial commands. This significantly reduces the host MCU's processing burden, allowing engineers to select less powerful, more cost-effective host processors or dedicate existing resources to core PQM functionalities like high-speed data acquisition and analysis. This streamlined architecture simplifies the overall system design and reduces hardware complexity.

Rapid Prototyping and Design Iteration

The graphical UI Editor and high-level programming capabilities mean that HMI design becomes a visual, drag-and-drop process. Engineers can quickly create, test, and modify user interfaces without deep embedded graphics programming knowledge. This rapid prototyping capability dramatically shortens design cycles, enabling faster iteration based on user feedback and accelerating time-to-market for new PQM products. The ability to preload TML files via USB further facilitates quick updates during development and deployment.

Long-Term Reliability and Consistent Performance

Designed for demanding industrial environments, Topway Smart LCDs offer robust construction and wide operating temperature ranges (-20°C to +70°C). This ensures consistent performance and extended operational life, even in conditions with dust, vibration, or temperature fluctuations. The unified body design enhances EMC performance , contributing to overall system stability and reliability, which is critical for continuous monitoring applications like PQMs.

Scalability Across Diverse Product Lines

The consistent architecture and development environment across Topway's Smart LCD series allow design engineers to easily scale their HMI solutions. Whether a PQM requires a compact 4.3-inch display, mid-size 7-inch screen or a more expansive 10.1-inch interface, the underlying principles of integration and simplified development remain consistent. This modularity in design approach, as seen in Industry 4.0 trends, enables engineers to maintain a unified HMI strategy across different PQM product variants, reducing re-engineering efforts and accelerating future product development.

| Feature / Model | HMT043BMC-1C | HMT070ETA-D | HKT070DMC-2C | HKT101AMC-C |

|---|---|---|---|---|

| Screen Size | 4.3 inch | 7 inch | 7 inch | 10.1 inch |

| Resolution | 480x272 | 1024x600 | 800x480 | 1024x600 |

| Touch Panel | Resistive Touch | Capacitive Touch | Resistive Touch | Resistive Touch |

| Interface | RS-485 | RS-232 | RS-485 | RS-485 |

| Operating Temperature | -20°C to +70°C | -20°C to +70°C | -20°C to +70°C | -20°C to +70°C |

Conclusion: Design with Confidence, Monitor with Clarity

The demands on Power Quality Monitors are escalating, requiring HMIs that are not only robust and reliable but also intelligent and easy to develop. Topway Smart TFT LCDs, with their integrated processing power, intuitive development tools, and industrial-grade durability, are engineered precisely for this challenge.

By offloading HMI complexity, accelerating design cycles, and providing crystal-clear real-time data visualization, Topway Smart LCDs like the HMT043BMC-1C and HMT070ETA-D empower design engineers to create superior Power Quality Management products. These displays do not just show data; they transform complex electrical information into actionable insights, ensuring optimal power quality and operational efficiency.

Empower your next PQM design with Topway Smart TFT LCDs – where intelligence meets industrial reliability. Explore how these smart display solutions can elevate your product, simplify your development, and provide unparalleled clarity in power quality monitoring.